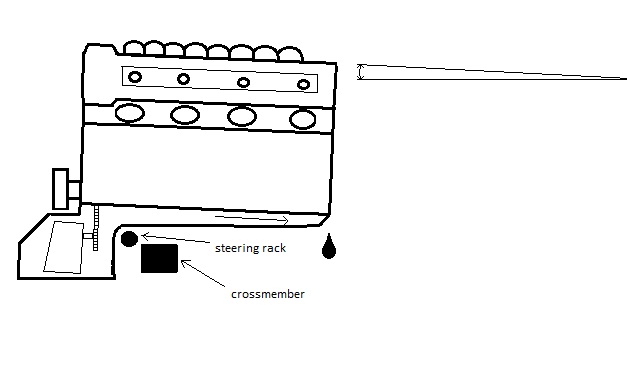

The BMW front-sump is the biggest problem with this installation, because it is right in the way of the Capri's steering rack and crossmember. The sump cannot be reconstucted to fall behind the crossmember because the oil pump sits down in the front sump and is driven from above by a chain from the crankshaft. Basically the oil pump needs relocating if it is to be retained at all.

My solution was to move the oil pump even further forward, and construct a new front sump that is almost completely in front of the engine and is far wider than it is long. This enables the engine to sit as far back in the engine bay as possible without refabricating the bulkhead/firewall. The new sump is a very tight fit between the anti-roll bar and the steering rack, with about 8mm clearance to each of these.

Other options could be :

a) Fit the engine so far back in the car that the sump goes behind the crossmember (this would mean completely reconstructing the bulkhead and moving the whole pedal assembly further back - and probably the driver's seat and steering wheel too).

b) Dry-sumping the engine, fitting a multi-stage scavenge pump and a custom made dry sump pan.

c) Reversing the hubs and moving the steering rack backwards to the other side of the existing crossmember position, then somehow reconstructing the crossmember much further back behind the new rack position. (reversing the hubs will cock up the Ackerman angle on the steering arms though unless they are redesigned or swapped for uprights from a car that has the rack in a rearward position.

d) Solid mount the engine to a custom sump that also forms a new structural crossmember and has the steering rack running through the oil reservoir itself.

This is the first sump i constructed. The oil pump has had the rotor swapped round so that the drive sprocket pokes out of the opposite side. This enables the pump to be moved forward to the other side of the drive-chain position, putting it forward of the steering rack and crossmember. The oil pump has one pair of bolts mounting it on the first main bearing cap, and the other two mounting bolts go into the front of the new sump where it oversails the front of the engine. The bottom of the sump is removable to allow the oil pump to be fitted.

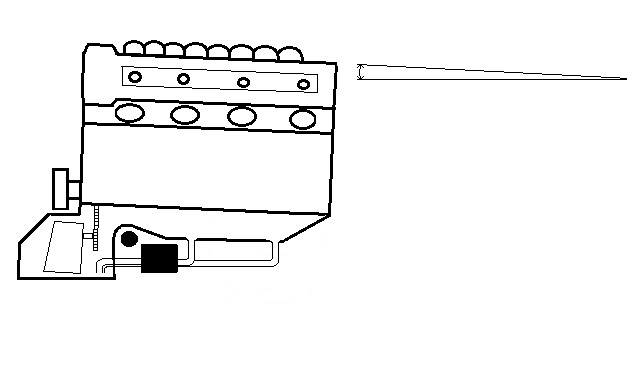

Side-view of the odd new sump profile:

The 2 larger holes in the block are the oil flow and return for the filter - see page on engine mounts for more info.

After driving the car for some time i kept getting a leak from the rear crank seal, on both the 530i and 740i motors. It couldn't just be a coincidence - turns out the angle of the rear part of the sump when in the car was flat or tilting back a few degrees, because the angle of the motor itself had ended up sitting back a lot or more than expected in the car to give enough clearance for the crank over the steering rack.

So at high rpm the oil ejected from the rearward galleries was just pooling and swamping the rear crank seal.

So the sump got a redesign:

The front container housing the oil pump remains the same put the rear section collects oil that is by then too low to pass over the height restriction of the steering rack, and then flows to the front section through a pair of flexible pipes that run through the crossmember itself.

The current setup works well but isn't too elegant.

I'm still not sure if it would have been wiser to keep the bmw sump and instead get rid of the original crossmember and rack position, and build a new crossmember far further back with the rack then mounted behind the front axle line. It would then also make sense to get rid of the capri front struts altogether and use struts & rack from a newer rwd car that gives the correct ackerman angle for a rear-mounted rack (and larger disks & calipers as standard).

A lot depends on budget and whether the car is going to keep its original chassis and suspension arrangement (and registration) or become more of a one-off modsport machine with entirely different running gear under the guise of a Capri bodyshell.

_____________________________________________________________________

The other most viable alternative is to fabricate a dry sump setup -

[the reservoir would have to go up inside the wing as there isn't room for it in the engine bay]

A dry sump setup is available for the M60 and M62 V8s from www.vacmotorsports.com designed for racing applications.

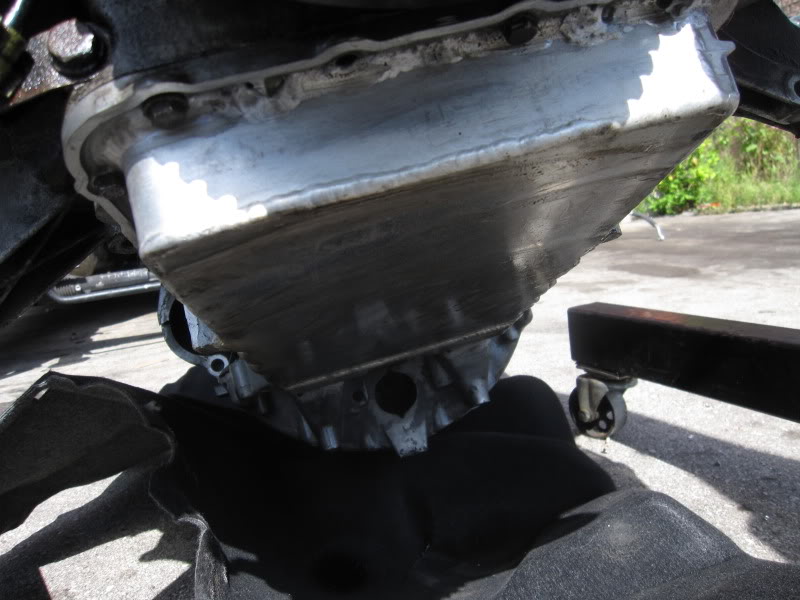

Here's a dry-sump that somebody's fabricated for the M60 V8 from aluminium using the rear and base portion of a standard sump. Can't see the oil pick-up positions but i'm assuming that they're down the right hand side.

A 4-stage dry sump pump available from www.motorsport.bdg.com.au

Similar sized 3 or 4-stage pumps are also available from www.paceproducts.co.uk

This diagram (courtesy of the BDG website) shows the layout of a dry sump system. Oil is scavenged (sucked) from several points on the engine (in our case it would all come from the sump) then it is lifted to a reservoir tank in the engine bay. From here oil is taken to the pressure-pump, through the filter, and into the main bearings and the rest of the oiling system.